Gojeep

Well Oiled

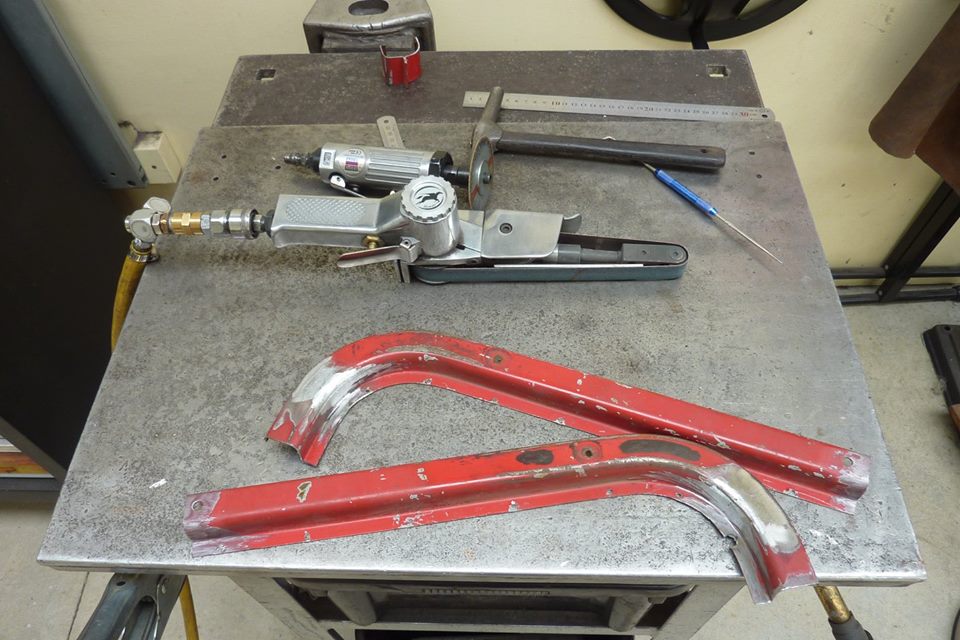

Taking on a half done project is never fun but got help a mate out so he can get back to driving this beast.

This is a friend of mine, Christos's Ratrod project that he has built from a 1948 Willys Truck cab with a 1950-53 front clip. 2wd with a Holden independent front end. The easy fun part of a 5.5" roof chop has been half done by a panel shop

Very nice blown mouse motor.

Ogre looking like he is trying to get out of jail! Some looking closely will see no radiator and think it does run yet. But it does as the radiator is behind the cab.

Ogre looking like he is trying to get out of jail! Roof has been pancaked 1", 1/2" less than mine but done in a completely different way. Rather than removing the roof skin, it has just been cut above the gutter, a strip cut out, and then put back down. Corners have had relief cuts to bend them in and then rewelded.

Concerns me that the roof is bowing downwards rather than upwards like the factory so the water spills off to both corners and out the slots that you can see one of. Window flange may no longer be at the same angle all the way along.

None of the pillars have been welded or fully aligned.

The rear wall caves inwards. Should be flush along the edge of the ruler. Just pulling the upper section out to meet the lower won't be enough.

Other side shows how the cut edge was not stretched back out before being tacked. It would have shrunk with the heat of the cutting.

For some strange reason the window was not kept whole and lowered with a step down cutout? Also not cut through the vertical section either.

There is not enough panel under the window flange to remove the 4", so some will have to come out of the back wall as well.

Problem is that the rear wall support could get in the way of the weld line and then access to hammer it out afterwards.

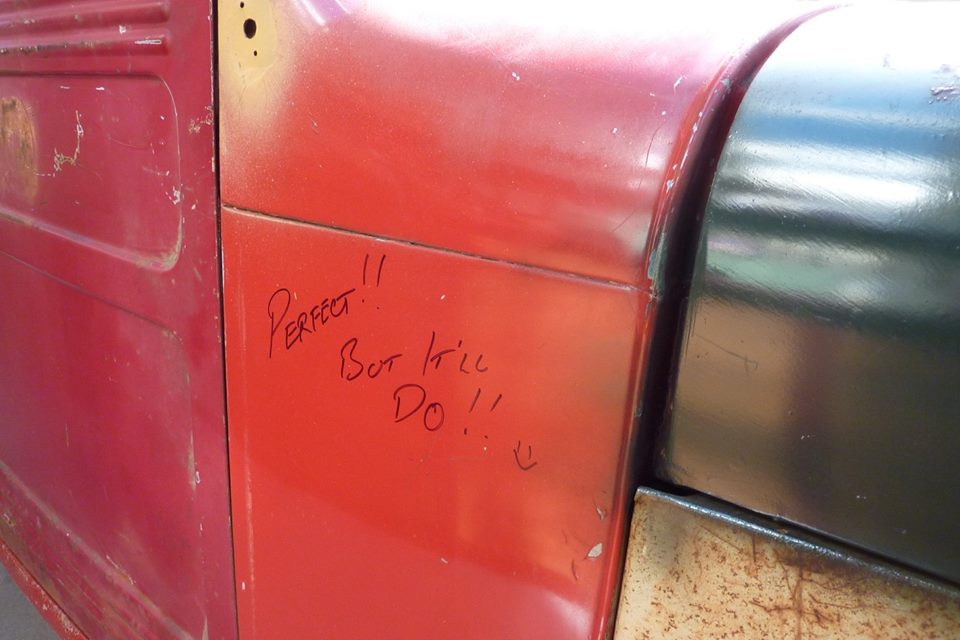

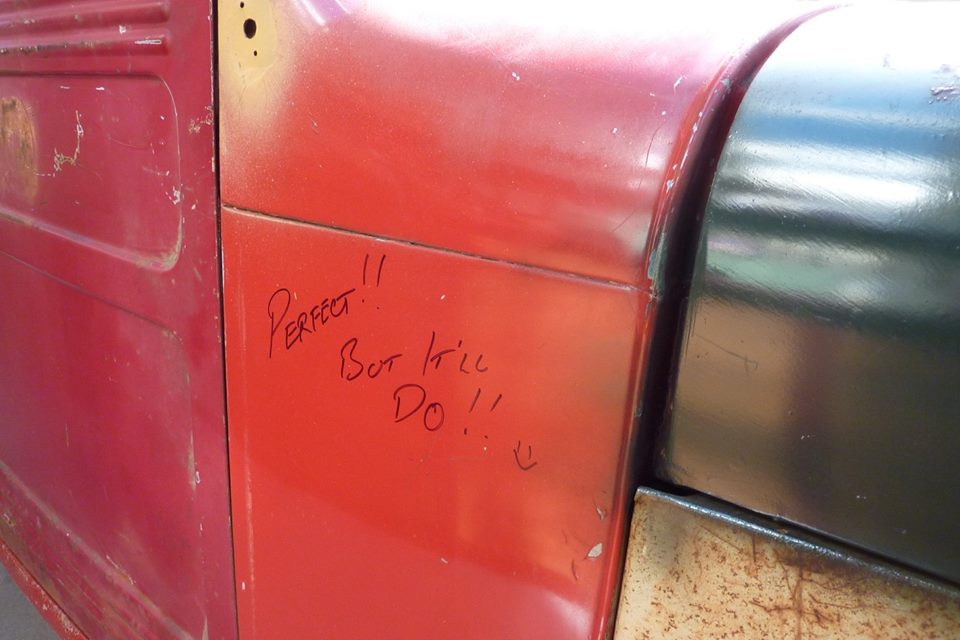

Maybe the panel shop left the word 'not' out in front of what they wrote!

Will weld up the old mirror holes.

Guard will need to be fixed.

The guard flapping around has caused another fatigue crack to occur

Old aerial holes need to be filled.

Centerpiece needs to be aligned and fully welded in.

Big gaps left.

Join does not look sound.

Other side the same.

Only 1/3 of the perimeter weld has been done.

So this is some of what I am starting with and will do my best to makes them right without taking too much time on it.

This is a friend of mine, Christos's Ratrod project that he has built from a 1948 Willys Truck cab with a 1950-53 front clip. 2wd with a Holden independent front end. The easy fun part of a 5.5" roof chop has been half done by a panel shop

Very nice blown mouse motor.

Ogre looking like he is trying to get out of jail! Some looking closely will see no radiator and think it does run yet. But it does as the radiator is behind the cab.

Ogre looking like he is trying to get out of jail! Roof has been pancaked 1", 1/2" less than mine but done in a completely different way. Rather than removing the roof skin, it has just been cut above the gutter, a strip cut out, and then put back down. Corners have had relief cuts to bend them in and then rewelded.

Concerns me that the roof is bowing downwards rather than upwards like the factory so the water spills off to both corners and out the slots that you can see one of. Window flange may no longer be at the same angle all the way along.

None of the pillars have been welded or fully aligned.

The rear wall caves inwards. Should be flush along the edge of the ruler. Just pulling the upper section out to meet the lower won't be enough.

Other side shows how the cut edge was not stretched back out before being tacked. It would have shrunk with the heat of the cutting.

For some strange reason the window was not kept whole and lowered with a step down cutout? Also not cut through the vertical section either.

There is not enough panel under the window flange to remove the 4", so some will have to come out of the back wall as well.

Problem is that the rear wall support could get in the way of the weld line and then access to hammer it out afterwards.

Maybe the panel shop left the word 'not' out in front of what they wrote!

Will weld up the old mirror holes.

Guard will need to be fixed.

The guard flapping around has caused another fatigue crack to occur

Old aerial holes need to be filled.

Centerpiece needs to be aligned and fully welded in.

Big gaps left.

Join does not look sound.

Other side the same.

Only 1/3 of the perimeter weld has been done.

So this is some of what I am starting with and will do my best to makes them right without taking too much time on it.

Last edited: